Our website uses cookies.

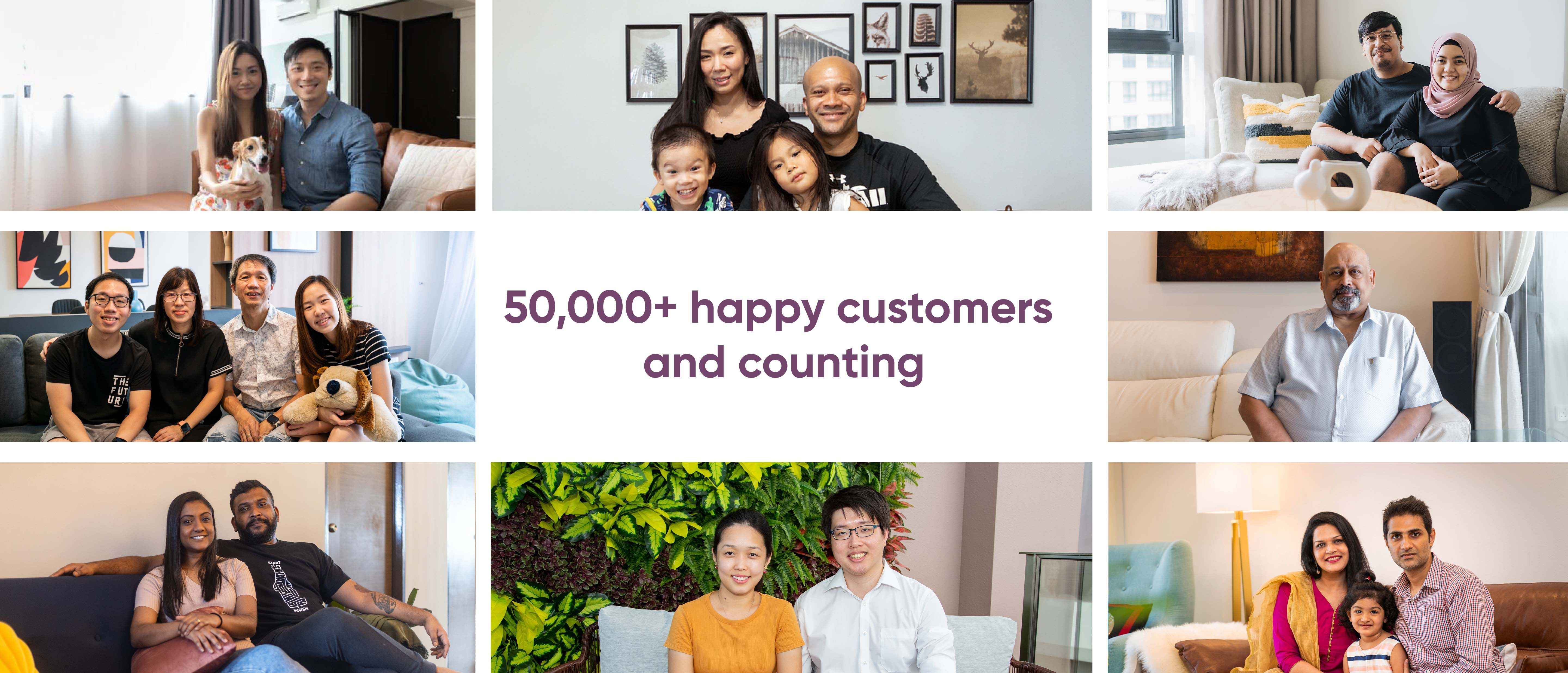

Learn MoreSomething big that changes an industry happens once in a lifetime. Here, you get a front row seat to how Livspace is changing the home interiors game — with automation from design to installation and quality home interior solutions with zero errors.

A journey through our revolutionary design-to-installation process

Precision engineering

for error-free and high-quality products.

4-sigma process¹

with 99.99% build accuracy

54,000 cabinets a month¹

ensuring you get your products on time.

Warranty built upon confidence

Our product range comes with a 5-year warranty² because of the confidence we have in our DurabuildTM cabinets. What are DurabuildTM cabinets? To Livspace, they are like the kids we are very proud of. The result of extensive R&D, they are the real heroes of our innovative solutions, offering unparalleled strength and durability.

What sets DuraBuild apart

-

Advance connector mechanism for robust cabinet construction.

-

Chipboard screws with PVC sockets ensure durability.

-

Soft-closing hinges reduce vibrations and extend cabinet life.

-

PVC legs for increased load bearing capacity (up to 350kg).

-

Designed with gaps from walls to prevent transfer of dampness.

Behind the scenes with a DuraBuild Cabinet

1. Design done right

Don’t wait for dreams

It all starts with capturing your dreams. Our proprietary design tool helps create 2D drawings in less than half the time required with traditional design tools and also converts 2D to 3D designs to help you visualize your future home.

What you see is what you get

Our proprietary design tool is also integrated with our factories, with files being machine-readable. This level of automation means no confusion or misinterpretation of drawings by factory staff, no manual entry of measurements and thus, no errors in the build. Just 100% accuracy.

2. Materials that withstand time

Finding the best and putting it to the test

The adventure begins with the search for the finest raw materials. Sourcing is done only from suppliers with the highest standards. Materials then undergo stringent testing, nothing is taken for granted and what you get is only the best.

- Moisture Tests

- Emission Tests

Moisture Tests

Checks for ideal moisture levels to ensure your panels don’t warp or crack in the long run.

Emission Tests

Confirms only highest grade materials are used, checks harmful emissions and ensures safe indoor air quality.

3. Precision in manufacturing

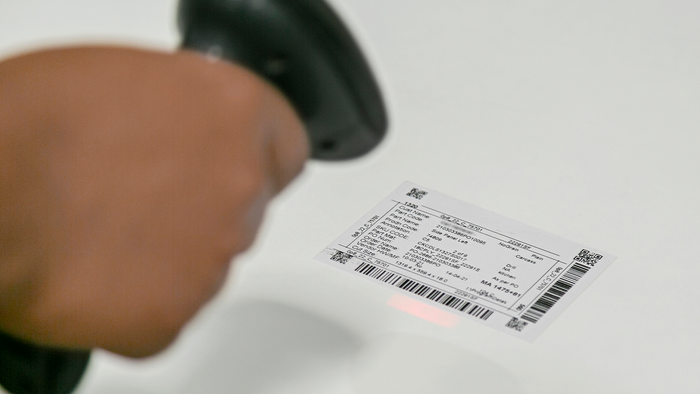

A programmed transformation

Machines interpret the files to perform the required tasks, while the automated management system uses QR codes on panels to control the production process seamlessly. This ensures zero human error.

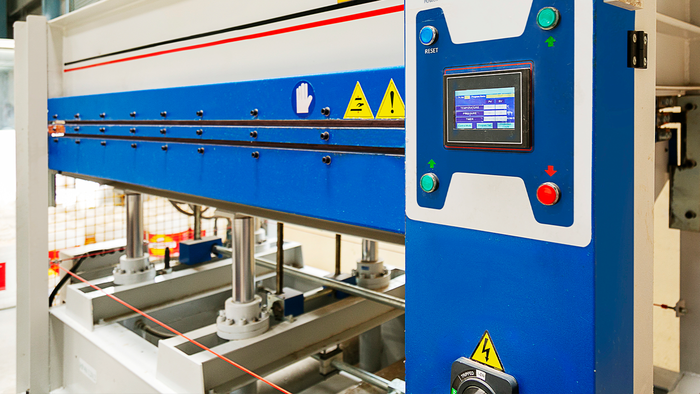

Materials bonding

Our AntiBubble® Technology now takes stage. The durable D3 glue is evenly applied with a roller. The finishes are then hot-pressed to the panels to ensure long-lasting superior bubble-free bonds.

For a smooth and seamless finish.

Making the perfect cut

Using the European beam saw (with no manual intervention), our panels are cut with hairline precision, ensuring no scope for error.

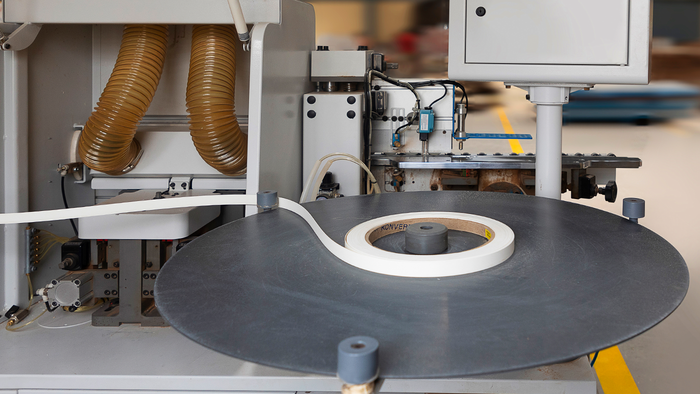

Sealed for endurance

Our AquaBloc® Technology uses an edge banding machine to seal the edges with thermoplastic glue. Now, moisture has no way to enter the panel ensuring the panel lasts long. The sharp edges are then smoothened out for comfort using a laser sensor.

Repels moisture from entering the core.

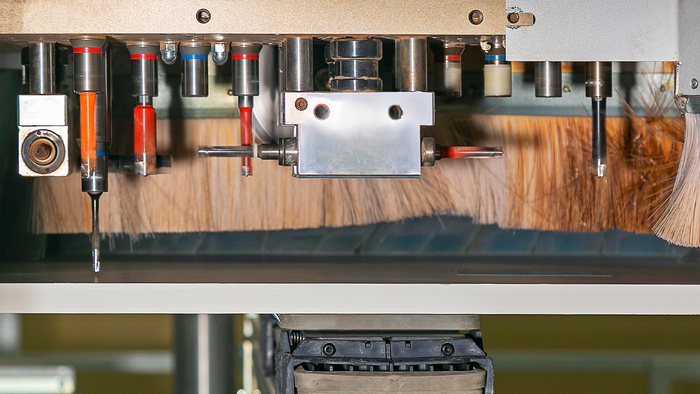

Getting the drill right

Second-guessing where to drill holes during installation creates undue drama like bad fits, tilted units or other compromises during installation. Our CNC machines read data off the drawings guaranteeing error-free drills and furniture that works beautifully.

4. Perfection through inspection

Highest quality standards

This is where we ensure your story gets a joyful ending. A dedicated team checks every single panel for any possible faults – like scratches, chip-offs, air pockets, sharp edges and errors in dimensions and colour shades – so that every custom cabinet you get is flawless.

5. Reliable packaging

Safety Wrapping

The panels that pass the quality checks are flat-packed. Special care is taken to safeguard glass shutters. Further, corner protectors, corrugated cardboard, bubble-wrap and tested packing procedures ensure zero damage during transit.

Drop Tests

Our packing materials are put through stringent drop tests before use to ensure the complete protection of finished products when they are packed.

6. Swift installation

Custom homes built for you

This is the final stage - assembling your dream home. The cabinets are smoothly assembled by our trained and certified experts, to deliver our promise to you.

Tested to be the best

Our success with custom cabinetry rest on superior design and material quality. Completely assembled cabinets are strength-tested for wear and tear as per German standards at independent labs. This process of qualification gives our cabinets the name of 'DuraBuild'.

Drawer Cyclic Test

Ensures extended life for your cabinet drawers.

Shutter Cyclic Test

Ensures long life for your shutters.

Vertical Force Test

Ensures superior hinge quality and avoids accidents.

Shelf Load Test

Ensures shelves don’t break under considerable load.