In This Article

- What Is IPS Flooring?

- What Is the Thickness of IPS Flooring?

- How to Install IPS Floors?

- What Are the Pros & Cons of IPS Flooring?

- IPS Floor Uses

- Differences Between VDF and IPS

- Differences Between PCC and IPS

- What Is the Cost Rate of IPS Flooring?

- Things to Keep in Mind When You Opt for This Material

- How Can Livspace Help You?

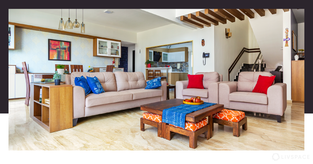

For a beautiful and long-lasting home, your base needs to be strong. That’s why the flooring you choose is one of the most crucial decisions you make while designing your home. You must’ve heard about different types of flooring like tiles, marble and wood. But have you ever come across IPS flooring? In this article, let’s take a look at this durable flooring option that’s becoming increasingly popular.

What Is IPS Flooring?

IPS, also known as Indian Patent Stone, is a type of concrete flooring material that is found in residential, industrial and commercial properties. The general concrete mix composition of IPS cement flooring is 1:1:5:3 (cement, sand and coarse aggregates). In addition, it is laid over a PCC of 1:4 (cement, sand and coarse aggregates).

Also Read: What Is Plywood and How Do You Pick the Best Plywood for Your Furniture?

What Is the Thickness of IPS Flooring?

The thickness of an IPS floor can vary from a minimum of 25 mm to a maximum of 75 mm. Ultimately, the thickness you choose will depend upon where you want to use this material.

- Residential: 25mm thickness (minimum wear and tear)

- Railway Platform: 50mm thickness

- Industrial: 75mm thickness

How to Install IPS Floors?

Like any other type of floor, installing IPS cement flooring requires the expertise of a professional. The steps to install IPS flooring are as follows:

- The surface must be cleaned with water and a brush

- To get an even level, a level mark has to be made on the surrounding walls via spirit levelling

- The next step is to construct a concrete dummy hole at a 2 to 3 sqm. area

- Next, the concrete mix is poured in

- The mixer has to be levelled with a trowel

- Cement slurry of 2 to 3 mm thickness is spread over the IPS floor to get a glossy finish

- To prevent cracks, curing needs to be done for 15 days. In addition, fibre can also be used

- Sometimes a vacuum dewatering machine is used to get a very hard surface

What Are the Pros & Cons of IPS Flooring?

Before you make a decision, you need to know the advantages and disadvantages of IPS flooring.

Pros

- Durable and long-lasting

- Looks attractive

- Energy-efficient because of its high thermal mass

- Moisture- and fire-resistant

- Has a low-maintenance cost

Cons

- Can be prone to cracks, if not cured properly

IPS Floor Uses

Indian patent stone can be used in the following cases:

- All types of flooring in homes

- Backsplash

- Industrial flooring

- Commercial flooring

Differences Between VDF and IPS

Vaccuum dewatering concrete flooring, also known as VDF, is a construction technique whereby a vaccuum is used to remove excess air and water from the concrete mixture before it is laid on the floor. This helps in improving the durability and strength of the floor.

| VDF Flooring | IPS Flooring | |

| Full form | Vaccuum Dewatering Concrete Flooring | Indian Patent Stone Flooring |

| Usage | Commonly used in high- traffic, industrial areas | Generally used for residential interiors |

| Cost | It can be expensive as it requires more skilled labour | It’s cost-effective as compared to VDF |

| Durability | Higher durability | Lower durability |

| Thickness | Minimum thickness of 30-35 mm | Minimum thickness of 25 mm |

Differences Between PCC and IPS

PCC or plain cement concrete is a mixture of cement, fine aggregates like sand and coarse aggregates without steel. This is generally laid over the soil surface so that there is no direct contact between the reinforcement of concrete with soil and water.

| PCC | IPS Flooring | |

| Full form | Plain Cement Concrete | Indian Patent Stone Flooring |

| Usage | Generally acts as a foundation or base layer | Used as a type of decorative flooring |

| Category | Comes under IPS | Comes over PCC as a protective surface |

| Cost | Economical | More expensive as compared to PCC |

Also Read: What is MDF Material? Is MDF Good for Home Interiors?

What Is the Cost Rate of IPS Flooring?

The price range of IPS flooring is around ₹60 to ₹80 per sq. ft. The actual cost may vary based on multiple factors like the size of your home, design, labour charges etc.

Wondering how much your kitchen will cost you? Use our kitchen cost calculator to find out.

Things to Keep in Mind When You Opt for This Material

If you have decided to go with IPS concrete flooring for your home, there are certain things that you must keep in mind:

- The finishing of IPS flooring cannot be paid for separately and is a part of the material

- IPS material can also be used for your dado

- Glass, aluminium or PVC strips need to be used in IPS

- Before you choose this type of material, determine your requirements and usage

- Carefully select the base foundation

How Can Livspace Help You?

- At Livspace, we provide high-quality, branded materials that go through 146 quality checks

- We provide a flat 10 year warranty*

- Our experienced designers can help you select the best flooring material as per your individual needs and budget

Book an online consultation with Livspace today. To know how our customers feel about working with us, check out these Livspace reviews for more details!

Have any thoughts or suggestions you’d like to share with us? We’re all ears! Drop us a line at editor@livspace.com.

Disclaimer: All contents of the story are specific to the time of publication. Mentions of costs, budget, materials, finishes, and products from the Livspace catalogue can vary with reference to current rates. Talk to our designer for more details on pricing and availability.

*For full scope of warranty, please visit livspace.com/in/service