In This Article

Fiber glass sheets have emerged as indispensable materials, offering a unique blend of strength, flexibility, and versatility. Join us as we explore how fiber glass sheets have revolutionised modern manufacturing and design practices, shaping the way we build, create, and innovate.

But, what is a fiber glass sheet?

Let’s ditch the technical jargon and get to the heart of fiber glass sheets! Imagine thin, super-strong glass fibers woven together like superhero hair, then fused with a plastic resin. This creates lightweight sheets that are surprisingly tough, able to withstand everything from harsh chemicals to fire and corrosion. The real magic lies in the strength-to-weight ratio.

Think of the glass fibers as tiny weightlifters, carrying the load, while the plastic acts as a supportive team, distributing the weight evenly.

This makes fiber glass sheets incredibly versatile, available in thicknesses ranging from a credit card to a thick chopping board. But how exactly is this magic made? Fiber glass itself is a combination of sand and common minerals, all melted and woven together with a special resin. It’s like a secret recipe with a few variations, depending on the desired properties.

What is a fiber glass sheet used for?

Fiber glass conduit

Fiber glass conduit offers a versatile alternative to PVC conduit across various sectors. Its exceptional corrosion resistance makes it particularly suitable for environments exposed to chemicals, such as wastewater treatment plants, chemical facilities, and coastal areas managed by port authorities.

Composite roofing

Most fiber glass roofs have a life expectancy of 20 years once they have been installed correctly. You can choose from a variety of trims to suit the roof build. Materials can also be easily cut to suit the shape of the roof. It also has no seams, which makes it waterproof.

Earthquake resistant bricks

Interlocking fiber glass sheets together can result in bricks that are strong enough to withstand earthquakes and other disasters. Additionally, they do not require cement or other bonding materials as this is internalised.

Transparent screen

Fiber glass insect screen will not rust, corrode, or stain. Fiber glass maximises the view by making it sharper and more brilliant. It has become the standard in window screen material over the last several decades.

Fiber glass rust proofing

Fiber glass roofing doesn’t rust, stain or corrode.

Also Read: The Best Guide on Wall Panelling Cost in India (Includes Types and Photos)

What are the different types of fiber glass sheets?

Fiber glass roof

Image source: Pinterest, @mila_gold2

Fiber glass roofing surpasses felt in durability and strength, boasting seamless construction that reduces the risk of water seepage and minimises failure points. Additionally, its ease of repair by professionals adds to its appeal. Consumers benefit from fiber glass roofing due to its remarkable durability, extended lifespan, and superior performance. This makes it great for gardens and patios.

Also Read: Green Thumb Galore: Beautiful Balcony Garden Ideas

Fiber glass wool

Image source: Pinterest, @decflans

Renowned for its exceptional insulating properties, fiber glass wool effectively regulates temperature, conserves energy, and dampens sound in various applications, from residential to industrial settings. Its flexibility allows for easy installation, conforming to irregular surfaces and ensuring efficient coverage. Additionally, fiber glass wool is fire-resistant, moisture-resistant, and resistant to corrosion, making it a durable and long-lasting solution for enhancing thermal and acoustic comfort while promoting energy efficiency. This kind of insulation is also great for industrial style design.

Fiber glass mesh

Image source: Pinterest, @parsonji

Crafted from fiber glass, insect mesh offers a lightweight and durable solution, favoured for its effortless installation, particularly for windows and doors. Its resilience against moisture and UV rays further enhances its suitability for outdoor applications.

Also Read: Granite vs Quartz: Cost-Effective Factors When Picking the Best Kitchen Countertop

E-glass (electrical glass)

Most typical form, and used widely for its electrical insulation properties.

S-glass (structural glass)

They’re used in military applications owing to their tensile strength and elasticity.

A-glass (alkali glass)

A-glass is best suited for applications that require contact with alkaline chemicals.

C-glass (chemical glass)

C-glass surpasses e-glass when it comes to durability, which makes it useful for chemical storage.

HR-glass (high resistance glass)

HR glass is capable of withstanding temperatures as high as 800 degree Celsius.

How are fiber glass sheets made?

Fiber glass sheets are manufactured through a meticulous process that harnesses the unique properties of glass fibers and resins. Here’s a detailed look at how they are made:

Raw material selection

The process begins with the careful selection of raw materials, including glass fibers and resins. These materials are chosen for their strength, durability, and ability to withstand various environmental conditions.

Fiber preparation

Glass fibers are produced by melting glass at high temperatures and then extruding it through fine openings to create thin strands. These strands are then wound onto spools for further processing.

Resin impregnation

A bath containing liquid resin is used to thoroughly soak the glass fibers, ensuring even coverage and impregnation. This resin can be polyester, epoxy, or other types, depending on the specific application and desired properties of the fiber glass sheets.

Formation

The impregnated fibers are then pulled through forming dies, which shape them into the desired profile or thickness. This process may involve heating to ensure proper curing and bonding of the resin.

Curing

The formed fiber glass material undergoes a curing process to harden the resin and create a solid composite structure.

Heat or UV curing activates the curing reaction, achieved through exposure to elevated temperatures or ultraviolet light, respectively.

Cutting and finishing

After curing, manufacturers cut the fiber glass sheets to the desired dimensions and may further process them by sanding, polishing, or applying coatings to improve surface properties and appearance.

Quality control

Manufacturers implement rigorous quality control measures throughout the manufacturing process to ensure that the final fiber glass sheets meet strict standards for strength, durability, and performance.

Packaging and distribution

Manufacturers package and prepare the finished fiber glass sheets for distribution to customers across various industries, including construction, automotive, marine, and aerospace. These sheets are utilised for applications such as roofing, cladding, insulation, and structural reinforcement.

Also Read: What Is HDF-HMR? Is It Better Than MDF and Plywood?

Advantages of fiber glass sheets

- Fiber glass is more lightweight than its alternatives, which makes it easier to work with. Also helps cut down on manpower

- It exhibits chemical resistance in various conditions

- It can be used for a variety of finished products, owing to its flexibility

- Completely non-magnetic, fiber glass also has UV resistance

- Can be used as is, without paint or polish, because of its resistance to rust, corrosion, and pests

Disadvantages of fiber glass sheets

- As flexible as fiber glass is, it can be quite difficult to achieve a seamless, refined look on it. Heavy layers of paint and polish need to be used to make it aesthetically pleasing.

- Compared to alternatives, fiber glass can be expensive. While very suitable for long-term use, customers can often be discouraged from investing in them because of the price point

- When it comes to certain metals and plastics, fiber glass can be a little fragile. Unless processed properly, fiber glass can have cracks

- Fiber glass sheets can be recycled but the process is complicated. This leads to a lot of mismanagement of waste, and can result in a negative impact on the environment

How can Livspace help you?

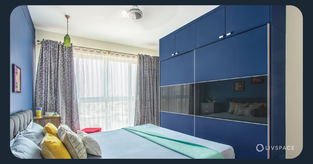

We hope this article about fiber glass sheets has put forward its complete uses. If you’re looking for ways to transform your house with eloquent designs, book an online consultation with Livspace today.

Our team of seasoned and creative designers is ready to collaborate with you to bring your vision to life.

- Our team can custom design your dream home with curated render designs and expert advice

- We have delivered over 75,000 happy homes

- We promise high-quality and durable materials